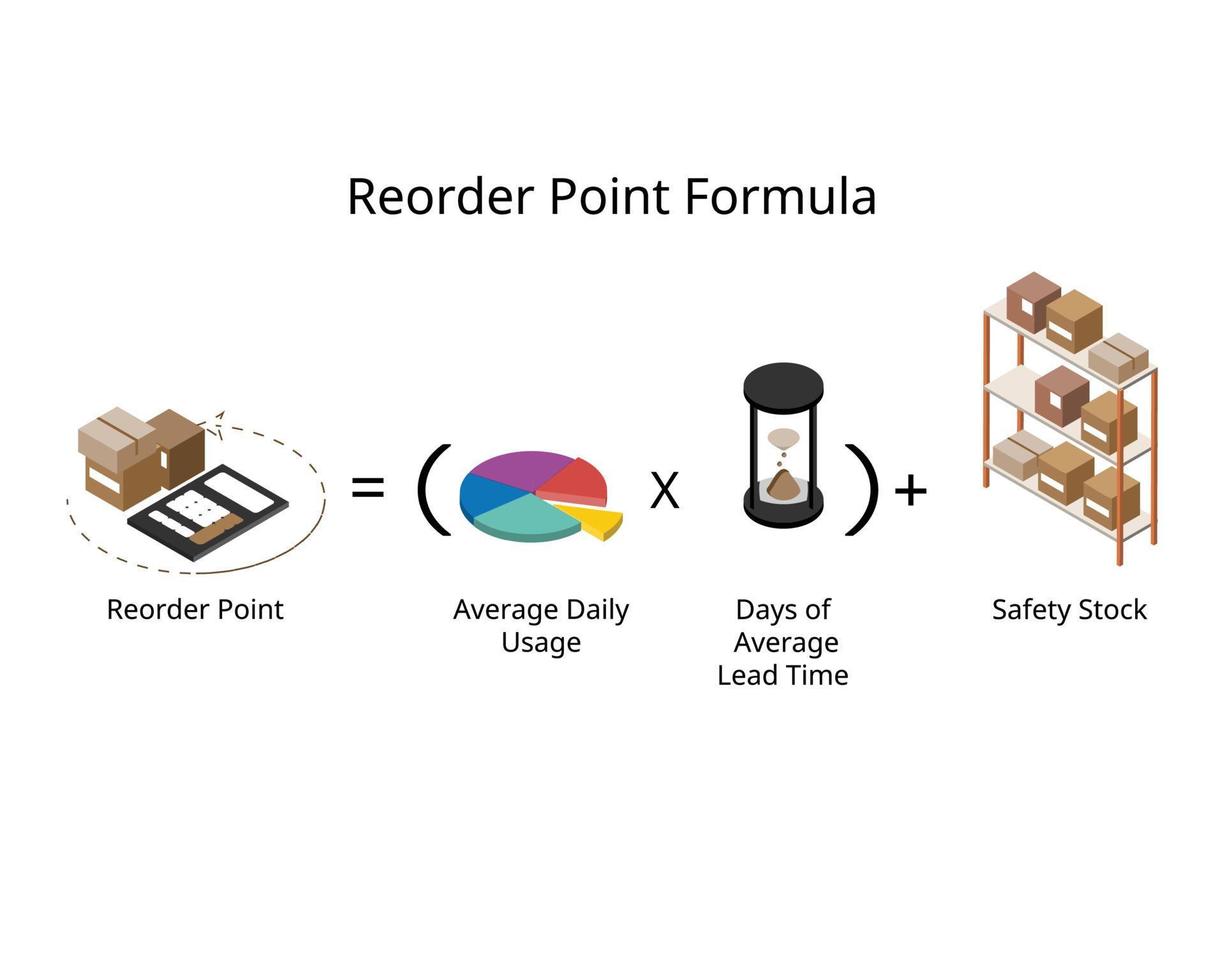

In management accounting, reorder level (or reorder point) is the inventory level at which a company would place a new order or start a new manufacturing run. In our example, 100 units per day multiplied by 14 days equals 1,400 units. First, identify the Average Daily Usage (ADU) by analysing sales or consumption data over a significant period, such as the past quarter or year. Calculate the total units sold or used, then divide by the number of days in that period. For example, if you sold 9,000 units over 90 days, the ADU would be 100 units per day. The reorder point formula is a dynamic model — all its variables will change over time, so your reorder point per item will change too.

The reorder point formula and calculation

In conclusion, mastering reorder level management is an ongoing process requiring attention, analysis, and adaptation. By applying the principles and strategies outlined in this guide, businesses can optimise inventory management, leading to improved operational efficiency and success. Supplier Reliability plays a crucial role in determining the aforementioned levels. Factors like order fulfilment rates, quality issues, and a supplier’s financial stability may necessitate higher reorder levels to ensure a sufficient supply of good stock. Finally, Economic Order Quantity (EOQ), though not a direct component, is related to reorder levels. EOQ determines the ideal order quantity that minimises total inventory costs, balancing holding and ordering expenses.

Experience Easier Calculations with Sourcetable

As we explained, you determine reorder points by multiplying your daily sales velocity by shipment lead time, and adding in any safety stock. If you notice a change in sales velocity or lead time, it’s time to set new reorder points. If you wait until you’ve run out of inventory to reorder, you’ll have a stockout until the shipment arrives and miss out on sales opportunities. Knowing how quickly your products sell and how long it takes for a new shipment to reach you can help you set reorder points and avoid stockouts. First you want to determine your demand during lead time by multiplying your daily sales by the lead time. Reorder point calculation ensures that you don’t fall behind on your next batch of inventory.

Gathering Essential Data

Now we’ll plug the figures from our example into the reorder point formula. The end result will produce an inventory quantity that will indicate when it’s time to order more. Customers come around, they’re checking the shelves, they’re looking for a certain product, but you don’t have it because you didn’t order enough or didn’t receive them on time. No matter what your category, if you have products you can’t sell, you either have to keep paying to store them, or you need to dispose of them, which also comes with a cost.

How to calculate total lead time demand

Keeping optimal stock levels in order to avoid stockouts is an integral task of inventory management. One of the most fundamental ways in which to ensure this is setting and maintaining the right reorder points. The reorder point formula is your average daily use, multiplied by your average lead time in days – plus safety stock. Businesses which follow lean inventory practices or a just-in-time management strategy usually don’t have safety stock. In such cases, your reorder point can be calculated by multiplying your daily average sales by your lead time. Typically, when you don’t have safety stock, your reorder level and the frequency of your orders tend to be higher.

- The longer it takes for you to receive new stock, the higher the reorder point would be and thus the longer your lead time would be.

- So there you have it, a complete guide to mastering the art and science of reorder levels.

- As an eCommerce business, you’ll likely be constantly looking for ways to make your operations more efficient and more cost-effective.

- Consider an eCommerce business selling 20 units of face serum daily with a lead time of 14 days and a safety stock of 50 units.

The ROP model is based on analyzing historical consumption and lead time data to predict consumption rates. Regular review and adjustment of reorder levels are necessary to maintain effectiveness in dynamic business environments. Efficient inventory management helps avoid stock-outs and excess inventory, improving cash flow, customer service, and profitability. Effective reorder levels also improve cash flow management by facilitating timely and appropriate ordering, preventing large, infrequent purchases that can strain financial resources.

If your order arrives too early, you could incur additional inventory storage costs. “Reorder point is calculated based on different factors of cost and risk, such as backlog and lost-sale costs, holding costs, fixed and variable ordering costs, ordering lead time, and others. For instance, if the backlog or lost-sale cost is much higher than the holding cost, the retailer should set a higher reorder point to avoid stockout, and vice versa. It’s very important to use a model that fits the business scenario of the retailer,” Miao says. Small and medium-sized enterprises (SMEs) can use reorder level calculations to minimize carrying costs.

Safety stock, as the name suggests, is the extra “just in case” inventory you keep on hand to anticipate variability in demand or supply. Too much inventory is expensive, but too little inventory can result in stockouts, which are harmful for your business. When orders are delayed or canceled because you don’t have the appropriate stock on-hand, you can lose customers and your reputation can suffer. When the inventory level reaches 350 units an order should be placed for material.

Businesses must consider factors like demand nature, lead time consistency, product characteristics, available technology, supply chain complexity, business size, and industry. The calculation consists of an item’s delivery time, demand the basics of reit taxation or consumption rate, and, if applicable, its safety stock level. Since all of these are dynamic variables, the ROP of an item can vary greatly depending on changes in the supply chain, market circumstances, selected suppliers, etc.

Its flexibility and responsiveness are well-suited for products with variable demand, fluctuating lead times, larger businesses, and rapidly changing markets. For instance, an online fashion retailer may increase reorder levels for popular t-shirts during the summer, considering recent sales trends and upcoming promotions. A fixed reorder level triggers an order when inventory drops to a predetermined point, regardless of other factors.